Problem Summary

Positive and promising news on the topic of home appliance technologies comes from the research department. Their specialists and technologists have recently developed a small yet impactful technical innovation as the new bimetallic thermal sensor. It provides the prospect of reducing the return of toasters under a one-year warranty. Experts’ estimated figures range from two to six percent; they also provided test results for old and upgraded toasters. Before introducing the bimetallic thermal sensor into production, it is necessary to verify the statement of the research department.

Description of Statistical Inference

The essence of this statistical inference is the use of numerical data provided by the research and testing departments. In order to verify the statement of statisticians and analysts, it is necessary to compare their expectations, which are in the form of a percentage, with the data of the test results. Data from the testing department will be converted to percentages to make this possible. Then, calculations will be made to identify real-life differences between test appliance returns. The final stage compares the actual percentage figures with the claimed confidential intervals. Usually, the confidential intervals, variability, and margins can contain a statistical error in this type of numeric data (National Emergency Medical Services for Children Data Analysis Resource Center, para. 8).

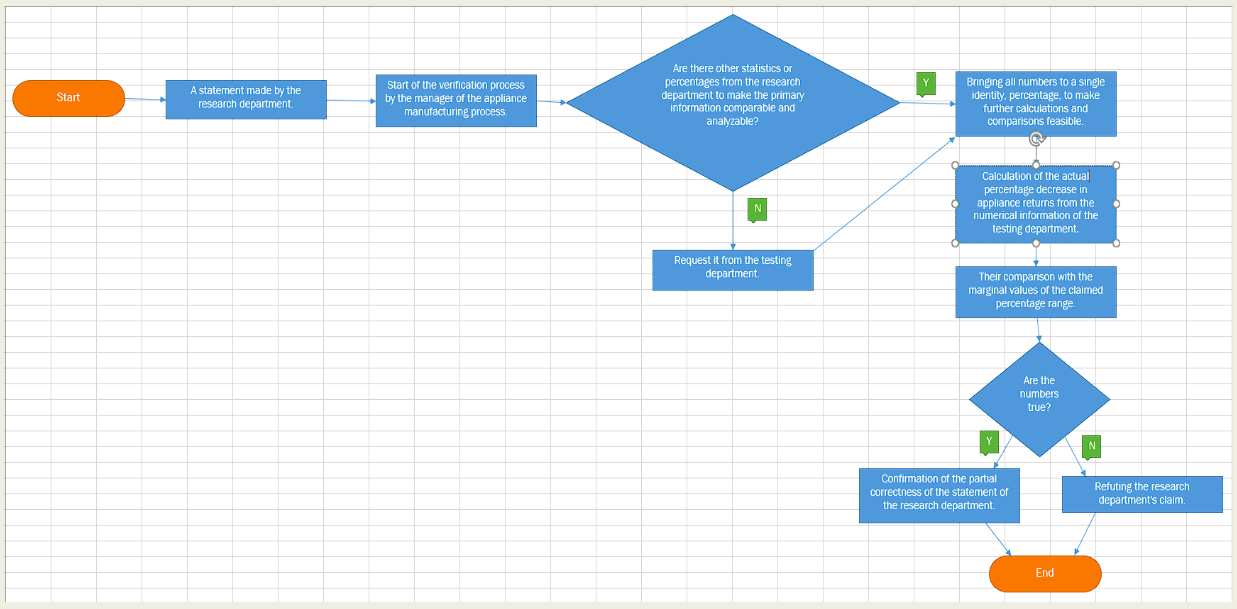

Statistical Inference Flowchart

It is a flowchart for the proposed statistical inference.

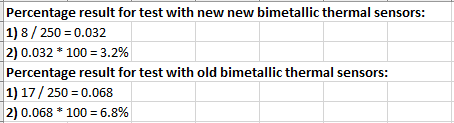

The first step in evaluating a research department statement is to verify the data provided by the testing department. Figures representing both experiments’ returned toasters and sample sizes were used to calculate percentages of appliance returns from the total. The results are 3.2% for toasters with new bimetallic thermal sensors and 6.8% for a one-year test procedure with old version items. The next and last computation steps are calculating the percentage difference and comparing the outcome with the declared range, according to which the product returns will go down.

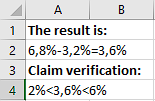

Calculations and Final Decision

Then comes computing the difference between the made percentages by subtracting the test results of toasters with the new bimetallic thermal sensors from those of the experiment with toasters with their old counterpart. It turns out that the most accurate and realistic indicator of how much the number of toaster returns by customers will decrease if the technical innovation is adopted into mass production is 3.6%. This figure is bigger than two and less than six; therefore, the research department was objectively correct in making claims about the potential productive impact of the newly invented thermal sensors.

Clarifications

As one can see, the research department has made objectively correct measurements about the potential ability of the new bimetallic thermal sensor to reduce the returns of toasters containing them in their structure. A minor statistical error in their estimations is that these are too broad relative to new, post- toasters test verification results. Three to four percent are more accurate with minimal and maximum values for their ability to improve quality. In conclusion, the analysts and statisticians of the research department made a mistake in calculating and defining confidence intervals.

Recommendations

The verification procedure showed not only a more accurate and realistic future percentage reduction in appliance returns possible due to the new bimetallic thermal sensor but also minor problems in the computation approach of the research department. Their researchers and statisticians are advised to improve their technique of sample size determination and variability calculations. Post-test calculations showed that 250 toasters were too small a sample size to accurately determine the possible positive impacts of the new bimetallic thermal sensor. According to statistics specialists, “a smaller sample size or a higher variability will result in a wider confidence interval with a larger margin of error” (National Emergency Medical Services for Children Data Analysis Resource Center, para. 8). Improvements in the mentioned areas will make business processes related to implementing technical innovations in the plant, warranty programs, and sales safer and more profitable.

The 3.6% reduction in test appliance returns is a good number for this novel technical innovation. The early introduction of new bimetallic thermal sensors into full-scale toaster production is highly recommended. Moreover, a small advertising campaign presenting the improved quality of the items and their new technical function would improve sales, increase business performance, and expand and optimize business processes.

Reference

National Emergency Medical Services for Children Data Analysis Resource Center. 2019. Confidence Intervals.