Apple products are popular due to their functionality and convenient design. The company constantly seeks new ways of enhancing its products through solid partnerships. Therefore, Apple uses various processes to continually improve its operations, products, service culture, and other critical organizational areas.

The processes the company employs are focused on the value of customers and innovation. In addition, Apple strives to develop a supply chain built not only on compliance but also shared responsibility between the company and suppliers. Keeping this in mind, the organization maintains the highest standards and rapidly addresses the issues in a way that prevents them in the future. For instance, it strictly follows its Human Rights Policy outlining the proper conduct to customers, partners, suppliers, and so further, which helps the company to move toward sustainable and responsible practices (Apple, 2022). As one can see, the company constantly integrates continuous improvement and operations excellence in its corporate culture.

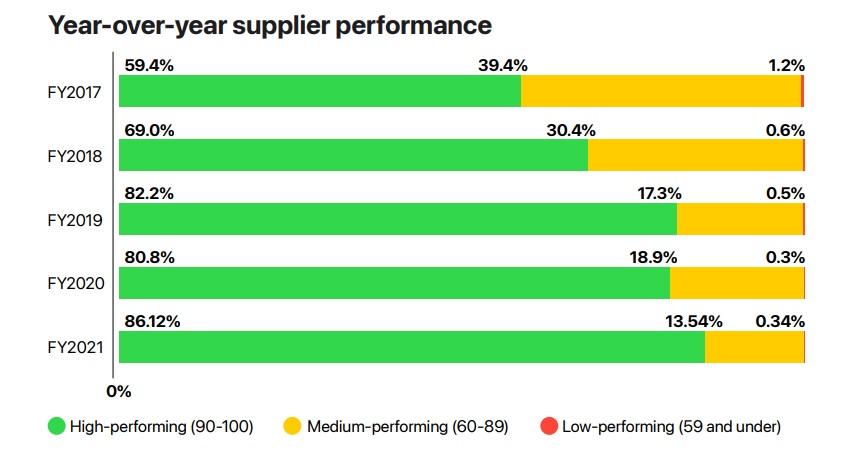

When looking at the interaction with supply partners, it is possible to admit that Apple puts much attention to ensuring their continuous and sound operations. One of the processes aimed at supplier performance improvement is capacity building. Corporate experts contribute to the optimization of supplier management systems (Apple, 2022). Apple divides suppliers into three performance groups, namely high-, medium-, and low-performance, according to the composite assessment score. Figure 1 below shows the advancement in supplier performance. According to the report, the company managed to drive improvements in supplier performance through compliance with the corporate working hours standard (Apple, 2022). As a result, Apple’s suppliers reached 95% compliance with these requirements and increased their performance by 2% (Apple, 2022). It suggests that along with setting high requirements for its suppliers, Apple helps them to develop and work independently without loss in quality.

Demand partners of Apple also help the company to develop in the direction of continuous improvement. For example, the partnership with Accenture helps Apple find new revenue streams, reduce costs, and advance the experience of customers (Apple, n.d.). Practices proposed by Accenture transform the principles of engagement between the organization’s clients and customers using Apple products (Apple, n.d.). It increases the demand for iPhones and iPad due to the convenience of these devices.

The SCOR metrics will be useful in evaluating the management processes of Apple. The corporate planning processes are centered around environmental challenges, and this responsibility represents a part of the strategic objectives (Apple, 2022). In terms of sources, Apple has a vast network of suppliers, the interaction with which is demonstrated in Figure 2. It has connections to the creation of ready-made products because the company embeds its high standards at the early stages of production. It impacts the processes of selecting suppliers and materials to ensure their high quality (Apple, 2022). As for the delivery of products, Apple offers the most rapid options for customers due to the huge availability of its official stores, as well as couriers (Apple, 2022). Thus, the company uses various management practices to keep its customers satisfied.

To conclude, Apple dedicates massive effort to continuous improvement and operations excellence. It builds robust cooperation with its suppliers and other partners, sets high requirements, and demands compliance with them, which leads to uninterrupted operations and quality products. It is the reason why Apple is still one of the leaders in the technology market.

References

Apple. (2022). People and environment in our supply chain: 2022 annual progress report. Apple, Inc.

Apple. (n.d.). Great partners bring great possibility. Apple, Inc. Web.