Introduction

The 21st century is characterized by the rapid evolution of the operational environment, in which modern firms compete for profits and growth. The development of new technological solutions requires companies to remain up-to-date and on par with their peers in this regard. In order to maintain the status quo and enable further sustained growth, organizations implement a framework of key activities that include operations management, quality assessment models, and supply chain management. These elements constitute a paradigm of resilience that directly affects the company’s growth. This report addresses the importance and value of these components for contemporary corporate entities.

Operations Management in Organizations

Examples of Business Operations

Business operations management (or OM) is one the vital components of a successful company that determines an entity’s ability to complete its tasks on a day-to-day basis and in alignment with its strategic vision. According to Moghadam et al. (2021), OM “involves complex interplays of people, technological systems, and organizational and physical processes, most of which change their nature over time”. Therefore, the complexity of the concept is further amplified by its extreme changeability in a globalized environment. Businesses want to remain in control of their operations, the variety and scope of which continue to grow (Choi et al., 2018). In this regard, it appears valuable to investigate actual examples of OM application and management in practice.

Retail is one of the vital industries that sustain humanity, enabling continuous economic exchange. One of the key varieties of OM in this regard is human resource management, which implies the creation of an efficient and positive work environment that contributes to the workers’ input and company growth (MIT, 2020). Amazon is one of the industry’s leaders that excels at most business operations in retail. Its distribution and revenue generation patterns are impressive, accumulating considerable income for the company as a result of efficient OM. However, Amazon’s performance in HRM has not been on par, resulting in bad publicity regarding the conditions of front-line employees (Cattero and D’Onofrio, 2018). Thus, the company’s operations management techniques need improvement in some areas.

Another interesting perspective on the use of operations management is represented by Saudi Aramco. This is one of the region’s petrochemical production and processing leaders. According to Patwardhan et al. (2019), Saudi Aramco relies on cutting-edge solutions in the organization of its business operations. More specifically, an emphasis is laid on the development of business analytics tools that advance the potential of the organization. The gradual development of such instruments allows Saudi Aramco to transition from a more detailed understanding of the current processes to advanced and accurate predictions regarding the efficiency of its future initiatives. This evolution pattern is described in Figure 1, showing the full spectrum of business analytics applications at Saudi Aramco. This nexus of human expertise and advanced technology contributes to the industrial superiority of the company.

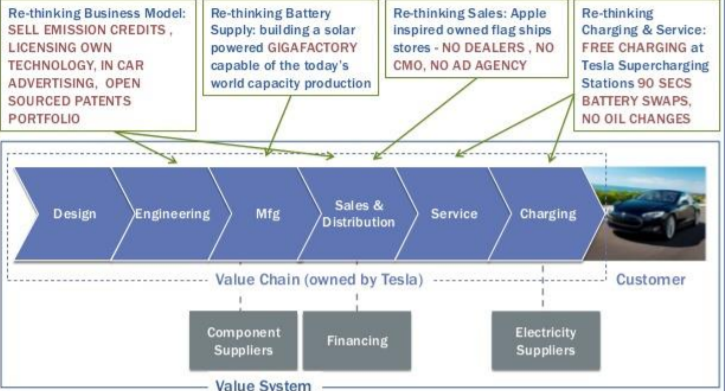

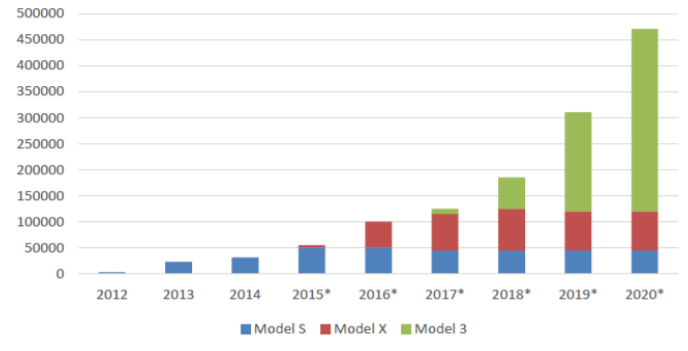

As research implies, the use of high-tech solutions is gradually becoming the central pillar of contemporary operations management. In addition to the case of Saudi Aramco, a similar tendency is observed in the automotive industry sector. Tesla Motors is one of its brightest representatives, combining decades of business expertise with a preparedness to venture into the uncharted territory of advanced solutions. Sathish (2020) emphasizes this information in his report, adding that Tesla actively embeds robotics, artificial intelligence, and the Internet of Things into its value chain (Figure 2). These efforts result in exponential growth of the sales levels, becoming the product of efficient business operations management (Figure 3).

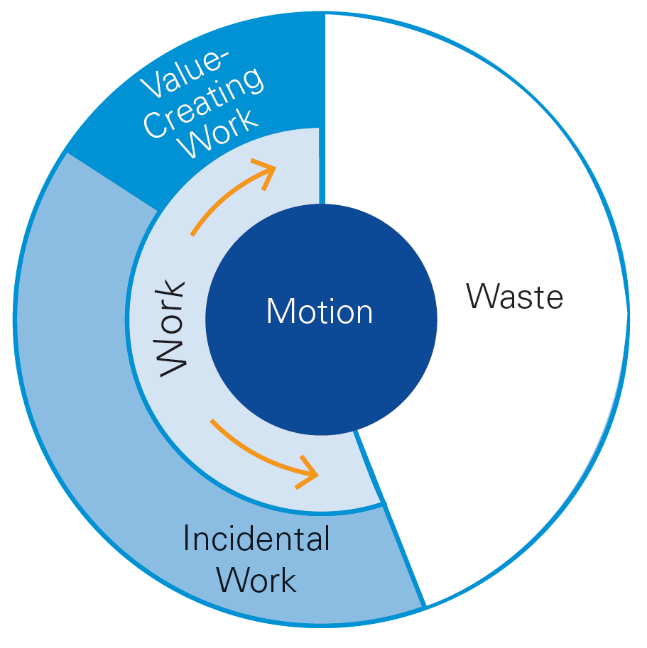

Process and Lean Techniques’ Contribution to Operations

Modern operations management tends to be driven by the lean principles embedded in the organizational value chain. According to the Lean Enterprise Institute (2021), this paradigm suggests the transition to a new framework, in which small, incremental changes contribute to sustained improvements within a corporate entity and the industry in general. As per the lean principles, the customer defines the value, whereas the organization should strive to achieve said value while eliminating waste (Figure 4). In this context, ‘the waste’ is a multi-faceted notion, comprising more efficient use of material, creative, financial, and human resources for the benefit of the end consumer. This approach is highly promising, as it aligns with the contemporary understanding of sustainable, customer-centric business.

The Role of Customer Service in Organizations

The enhancement of the value chain in compliance with the lean principles relies, among other key factors, on superior customer service. Rosin et al. (2020) remind us that the value is defined by the customer in this scenario. In other words, the desirable outcome of business operations is created by the consumers’ perceptions and not the company’s inner aspirations. Manufacturers and service providers are to adopt a perspective that aligns with the expectations of their target audience. Customer satisfaction is a major component of this outcome, and it is achievable exclusively through superior customer service.

Quality Models, Systems, and Standards

Evaluation of Quality Models, Systems, and Standards

Companies implement various quality-assurance models to sustain their value chains. Bacoup et al. (2018) introduce two leading approaches to quality standards in the contemporary environment. The first one is ISO in its current ISO 9001 form. This standard is developed by the International Organization for Standardization (2022) that seeks to ensure that the perspectives on value and quality are in line within modern globalized markets. Simultaneously, lean management introduces its own view of quality, as defined by the customer-centered paradigm.

Examples of Quality Models Use

Table 1. Quality Standards across Different Industries

Quality Model Use Advantages and Disadvantages

As can be inferred from the information provided in Table 1, most products and industries on an international level continue to adhere to the principles of ISO quality assurance standards. This tendency is explained by the profound nature of ISO (2020) research that is based on decades of industrial experience. The regulator seeks to create uniform standards for a globalized economic space, which would support the transparency and reliability of global trade. At the same time, as implied by Bacoup et al. (2018), ISO standards diverge from the principles of lean management, which gain weight in the contemporary environment. This is explained by the importance of various perspectives’ coordination within the ISO framework. Lean principles are more up-to-date, but they lack the so-called ‘test of time’, meaning that their long-term applicability, safety, and efficiency is yet to be acknowledged by the world’s industrial community.

Supply Chain Management and Operations

Example of Supply Chain Theories and Models

Supply chain management is another essential component of a thriving business of the 21st century. Within its framework, the emphasis is laid on the efficient interaction between suppliers, manufacturers, and distributors (Nunes et al., 2020). This way, products are made and delivered to the end consumer with maximum efficacy, minimizing the costs and maximizing the value (Ben-Daya et al., 2019). Figure 5 introduces the basic schematic representation of supply chain management and its key elements. As it implies, there are several prominent links within the chain, the sequence of which, as well as their relations, determine the viability of the supply chain. These components account for the variability of supply chain management patterns.

As established above, Tesla is one of the most innovative companies within the automotive industry and in general, which is equally reflected in its approach to supply chain management. The company pursues a mixed paradigm of SCM, combining conventional practices with innovative alternatives whenever applicable. In terms of inbound logistics, Tesla relies on an array of scarce materials, which limits the company’s choice of suppliers. Its strategy shines at the stage of outbound logistics and distributions, at which the company alters the conventional methods of dealership distribution (Dudovskiy, 2021). Instead, Tesla works directly with its customers, avoiding the intermediary, which is possible through effective marketing operations. This model has yielded positive results through an effective combination of standard practices and innovative techniques of product distribution.

Saudi Aramco represents another approach to supply chain management, which is conditioned by the operational environment of the company. Being one of the world’s leading producers of petrochemicals, this organization relies heavily on the quality of raw materials. According to Attia et al. (2019), Saudi Aramco’s operations engage hundreds of suppliers to diversify its inbound logistics. This is done to ensure the company’s resilience, as major interruption at this stage undermines Saudi Aramco’s ability to meet the customers’ needs. The demand for petrochemicals is on a stable increase, which leaves little or no room for such interruptions. Thus, the company seeks to maintain the resilience of its supply chain through diversification of inbound raw material supply.

Finally, Amazon is a company that relies heavily on supply chain functionality, as conditioned by its position as one of the leaders of global retail and e-commerce. The company pursues a larger scale of its distribution operations, which consists of building a broad network of warehouses and storage units. Combined with a diverse delivery fleet, this approach allows Amazon to optimize its shipment time, presenting speed as a competitive advantage. Being a highly advanced e-commerce retailer, this organization equally employs a number of advanced solutions in terms of predictive analytics. This step determines the exact contents of their warehouses based on historical data and predictive analytics. Thus, ‘waste’ is minimized, as prescribed by the lean principles, which play a major role in Amazon’s supply chain management patterns (Qin and Liu, 2022). This is an example of the correct implementation of advanced solutions into a supply chain, which enhances customer experience and generates better returns for the company.

Logistics and Suppliers in Supply Chain Management

Supply chain management imply efficient connections between its various elements, such as procurement, distribution, and others. While these elements can be arranged in varying patterns, these connections are equally important. They are represented by the concept of logistics, which refers to the delivery of materials and goods between the elements of a supply chain. Logistics play a role of paramount importance in supply chain management, as they reflect the viability of the SCM strategy (Maric and Opazo-Basaez, 2019). When executed correctly, it minimizes costs while ensuring the resilience of the chain. If the logistics component remains flawed, the link between the supply chain elements is broken, compromising the integrity of the whole framework.

Supplier relations are another essential determinant of success. In fact, suppliers represent the origin point of all supply chains, meaning that problems at this stage entail major complications along them (Cole and Aitken, 2019). When contracting a supplier, several major factors should be taken into account. First, the raw materials’ quality is on par with the desired product outcome. Second, the volume capacity of the supplier is to match the goals of the manufacturer. Finally, a stable supply is to be ensured, allowing for the uninterrupted functioning of the supply chain.

Conclusion

Overall, operations management plays a prominent role in today’s business environment. With the globalization and digitalization of business processes, the competitive landscape becomes more intense, prompting decision-makers to seek new effective solutions. Operation management is an indispensable element in this regard, as it serves as the key link through which strategic vision translates into reality. This concept is multi-faceted and complex, but it should not be underestimated by modern companies willing to achieve success.

Reference List

Attia, A. M. et al. (2019) ‘Data on an upstream segment of a hydrocarbon supply chain in Saudi Arabia’, Data in Brief, 27, 104804.

Bacoup, P. et al. (2018) ‘From a Quality Management System (QMS) to a Lean Quality Management System (LQMS)’, The TQM Journal, 30(1), pp. 20-42.

Ben-Daya, M. et al. (2019) ‘Internet of things and supply chain management: a literature review’, International Journal of Production Research, 57(15-16), pp. 4719-4742.

Box Around the World. (2019) Supply Chain Management. Web.

Cattero, B. and D’Onofrio, M. (2018) Organizing and collective bargaining in the digitized “tertiary factories” of Amazon: a comparison between Germany and Italy. In: Ales., E. et al. (eds.), Working in Digital and Smart Organizations. Palgrave Macmillan, Cham.

Choi, T. M. et al. (2018) ‘Big data analytics in operations management’, Production and Operations Management, 27(10), pp. 1868-1883.

Cole, R. and Aitken, J. (2019) ‘Selecting suppliers for socially sustainable supply chain management: post-exchange supplier development activities as pre-selection requirements’, Production Planning & Control, 30(14), pp. 1184–1202.

Dudovskiy, J. (2021) Tesla value chain analysis. Business Research Methodology. Web.

ISO. (2020) ISO 29001:2020. Web.

Lean Enterprise Institute. (2021) Operations. Web.

Maric, J. and Opazo-Basaez, M. (2019) ‘Green servitization for flexible and sustainable supply chain operations: a review of reverse logistics services in manufacturing’, Global Journal of Flexible Systems Management, 20, pp. 65–80.

MIT. (2020) Role of retail operations management in retail. Web.

Moghadam, M. R. S. et al. (2021) a review of case study method in operations management research, International Journal of Qualitative Methods, 20.

NQA. (2021a) Food & beverage industry standards. Web.

NQA. (2021b) Automotive industry standards. Web.

Nunes, L. J. R. et al. (2020) ‘Biomass for energy: a review on supply chain management models’, Renewable and Sustainable Energy Reviews, 120, 109658.

Patwardhan, R. S. et al. (2019) ‘Applications of advanced analytics at Saudi Aramco: A practitioners’ perspective’, Industrial & Engineering Chemistry Research, 58(26), pp. 11338-11351.

Qin, Y. and Liu, H. (2022) ‘Application of value stream mapping in e-commerce: a case study on an Amazon retailer’, Sustainability, 14(2), 713.

Rosin, F. et al. (2020) ‘Impacts of Industry 4.0 technologies on Lean principles’, International Journal of Production Research, 58(6), pp. 1644-1661.

Sathish, S. (2020) Case study of Tesla: supply chain challenges and enablers. Academia. Web.